Chemtop 1000 FG Wall Coat

A 3 -component, solvent free, self-levelled food grade epoxy wall coating. Itis a type of epoxy resin that is specifically formulated to be safe for use in food-contact applications

Product Description

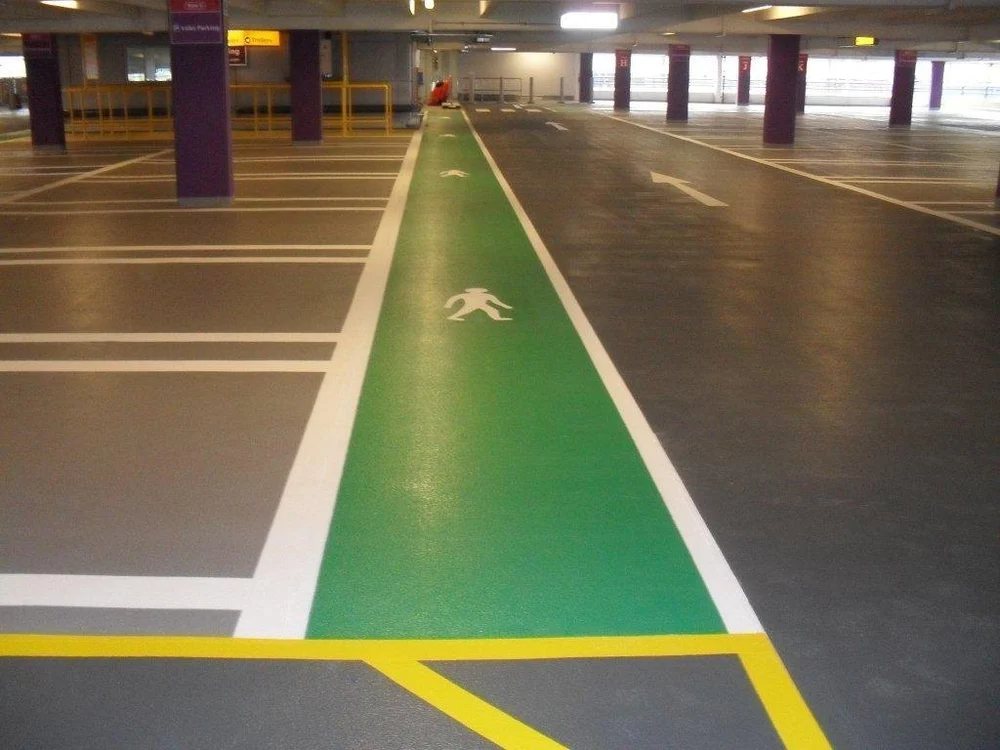

Uses

- Food and Beverage Packaging: Food-grade epoxy is often used in the manufacturing of food and beverage packaging materials, such as cans, containers, and lids.

Food Preparation - Rooms/Shades: Epoxy coatings can be used to seal and protect the concrete/metal surfaces in commercial kitchens, including countertops, cutting boards, and worktables. This provides a smooth, non-porous surface that is easy to clean and prevents the growth of bacteria.

Salient Features

- Non-Toxic and Food Safe: Food-grade epoxy is formulated to be non-toxic and safe for direct contact with food and beverages. It does not leach harmful chemicals or substances into the food, ensuring that it maintains its quality and safety.

- Chemical Resistance: Food-grade epoxy is resistant to a wide range of chemicals commonly found in food and beverage processing, including acids, alkalis, oils, and cleaning agents. This resistance helps maintain the integrity of the epoxy coating and prevents degradation.

- Temperature Resistance: Food-grade epoxy is designed to withstand a range of temperatures typically encountered in food processing and storage. This includes both hot and cold conditions, ensuring that the epoxy remains stable and does not release harmful compounds.

- Smooth and Non-Porous Surface: Food-grade epoxy creates a smooth, non-porous surface that is easy to clean and does not allow the accumulation of bacteria, mold, or other contaminants. This feature is crucial in maintaining hygiene in food processing and preparation environments.

- Durability and Wear Resistance: Food-grade epoxy coatings are known for their durability and resistance to wear, impact, and abrasion. This makes them suitable for use in environments where surfaces may experience frequent use and handling.

- Adhesion Strength: Food-grade epoxy creates a strong bond with various substrates, including metal, glass, ceramics, and some plastics. This ensures that the epoxy coating remains securely attached to surfaces even in demanding conditions.

- Low Odor and Low Volatile Organic Compounds (VOCs): Food-grade epoxy is formulated to have low levels of volatile organic compounds, which means it emits fewer odors and potentially harmful gases. This is important to maintain the sensory qualities of food products and ensure a safe working environment.

- Regulatory Compliance: Reputable food-grade epoxy products are compliant with relevant food safety regulations and standards set by organizations such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). Compliance ensures that the epoxy meets established safety criteria.

- Very Easy to Apply

Technical Profile

Mechanical/Physical properties

| Property | Test Method | Value and Unit |

|---|---|---|

| Mixing Ratio | NA | Pre-weighed kit |

| Finish | CPI* 1001 | Non-porous, Smooth, Glossy |

| Pot Life @ 30°C | CPI 1002 | 30–35 minutes |

| Surface Dry | CPI 1002 | 3 Hours |

| Hard Dry | CPI 1002 | 24 Hours |

| Full Cure | CPI 1002 | 72 Hours |

| Abrasion Resistance [Taber] | ADTM D 4060 | 60 mg loss |

| Shore Hardness | ASTM D 2240 | D 80 |

| Service Temperature | CPI 1122 | 0–50°C |

| Shelf Life | – | 12 months in original unopened container when stored between 10–30°C |

| Amount of Extractives | USFDA-175.300 | 0.048 mg/in² |

Method of Application

All Chemsol Products are recommended to be applied only by Approved Applicators and should be handled after using proper PPE’s like Gloves, mask, goggles etc.

1. Surface preparation:

- Surface should be clean, dry, and in sound condition.

- All the surface dirt, grease, and loose particles should be removed from the surface, and the surface should be washed thoroughly with clean water.

- All other previous coatings, if any, shall be completely removed.

2. New Surfaces:

- The newly constructed surfaces shall be completely cured before coating application.

3. Cracks and Joint Treatment:

- All the surface cracks from 0–5 mm shall be opened with a 3 mm angle grinder.

- The opened cracks shall be cleaned properly and filled with a suitable acrylic crack-filler.

- Cracks more than 5 mm should be repaired using polymer-modified mortar using Chemsol Chemfast SBR with a cement-sand ratio of 1:3 and polymer content of 10% by weight of cement. Allow it to cure as required.

4. Priming:

- Apply one coat of Chem Prime. The priming coat shall have a coverage of 80–100 Sqft/Lit.

5. Application:

- Apply the 1st coat of Chemtop 1000 FG on the primed surface with a roller or brush. The coverage of 0.15 L/Sqm/Coat shall be maintained on the surface. The coating shall be allowed to cure for 6 hrs before the application of the second coat.

- The second coat of Chemtop 1000 FG shall be applied over the first coat. The coverage of 0.15 L/Sqm/Coat shall be maintained.

- Let the coat cure for 7 days.

Precautions and Limitations:

- Do not dilute with water.

- Keep the material closed when not in use.

- Do not apply when rain is expected in a short time span.

Curing Schedule

| Temp (°C) | Foot Traffic | Full Cure |

|---|---|---|

| 10°C | 48 hours | 120 hours |

| 20°C | 36 hours | 96 hours |

| 30°C | 24 hours | 72 hours |

Cleaning Tools

Packing

Storage conditions

Handling & Safety

*Disclaimer: The information provided is based on our experience, thorough investigations, and sophisticated testing methods, but due to the vast number of applications and usage methods, Chemsol Polymer Industries cannot accept responsibility of any kind for any particular result. It is the responsibility of the user to verify the suitability of the product for their end use and in accordance with the rules and regulations of that country/territory. All information provided pertaining to our products should be treated only as a guidance tool without any guarantee or warranty of any sort.

*All CPI test methods are our scientifically designed internal test methods, which can be shared upon request.